Purchasing management and internal collaboration

- Details

- Category: Purchasing Management

- Hits: 16,940

Strategic purchasing is most often associated with external relations. However, purchasing integration and internal collaboration are the enablers of every corporate strategy. The aim of this chapter is to explain the connections between purchasing and the company's competitive priorities as well as emphasize the need for interdepartmental collaboration.

Many literature sources across disciplines have described collaboration as interaction, where communication in the form of meetings and information flows are employed to bond departments. Communication by way of task forces was always an important integration mechanism during the start-up and final stages of product development. Souder (1977) defines the interdepartmental collaboration as "A state of high degrees of shared values, mutual goal commitments, and collaborative behaviours Nowadays companies more often send to the markets highly complex products and related services.

It all requires solid external actions but also necessitates close cooperation between departments within the company where everyone has common goals and understands the importance of communicating with others.

Importance of internal collaboration

Interdepartmental interaction represents the communication aspects associated with activities performed by different departments within a company. Such activities address verbal and documented information exchanges between specific sides; therefore they correspond to both tangible and intangible assets of the company .

All the activities should be well structured, clarified and standardized whenever it is possible. If the work division is not clear employees may become confused over their roles in the collaboration processes that can contribute to frustration and serious corporate problems.

Also, if inefficient, collaboration can be time-consuming and can impact negative outcomes i.e. lack of agreement and understanding between leaders and other participants (Shani, et al., 2008), . Therefore it is necessary to define the meaning of collaboration in each company and set the standards for effective information sharing and integration.

As mentioned in part purchasing organization should be the enabler for effective internal cooperation as well as collaborative with other departments i.e. by using cross-functional teams and leadership. The concept of cross-functional teams has been lately brought up as an efficient tool to manage expectations of the departments and the company.

While it is fairly simple in theory, its practical implementation is very often difficult. A lot of firms must change their business behaviour and overcome previously established functional structures of reporting and sharing information. Powerful cross-functional integration requires a corporate culture of participative teamwork within all company's levels and across defined functional limitations.

It is important to define responsibilities of purchasing organization and other organization inside the company e.g. manufacturing, R&D, logistics, marketing. Therefore there should exist so called “department-specific activities” in order to clearly define internal competences. Some of them would be interrelated but the rest would reflect low interdepartmental interaction and low interdepartmental collaboration, since activities would be internal to the department. Nevertheless, introduction of new products and product changes very often requires collaboration of several departments. In such cases the purchaser's knowledge should be supported by engineers, a development team and sales representatives. It is the common view that provides the best decisions and results.

Following the discussion it can be stated that purchasing integration involves the active participation of purchasing in the strategic debate in the corporation and is aimed at promoting the alignment of purchasing practices and goals with strategic business priorities. Purchasing integration relates purchasing plans and practices to business vision, and shapes senior management's perceptions of procurement's strategic role in the firm.

Some of the field researchers, however, argue that sometimes interdepartmental discussion meets a lot of problems. Collaboration is understood as an involved process where employees may not be productive because of time and resource spent to take part in cross-functional training and related activities. Such actions without immediate results might be undesirable from upper management's perspective.

Thinking in terms of transactions, departments are considered to be independent entities that may compete for company's resources, and the collaboration between specific departments is considered to be occasional and cost-incurring. Due to competition and perceived costs, managers view meetings and information flows with other departments as negotiations, where each department tries to get the best deal at the conclusion of the meeting or information exchange.

It is important to point out that the level of purchasing success and the following success of the company depends on the fit between the company's functions. In case of purchasing initiative, a structure should be established to enable cooperation with other departments. The departments should give each other a mutual support in order to improve overall company's performance. When setting up collaboration processes, issues like division of responsibilities, field support and information sharing should be determined.

By establish the purchasing department's fit into the company's other functions it also creates a support for already established collaboration to improve and deliver outcomes that are in favour for the business performance. Further, it can be observe that the level of involvement of purchasing organization depends on a project and its complexity. Sometimes the internal focus of a project may lie in other departments e.g. manufacturing and product development. Despite the less important role of purchasing in some cases, it is still necessary to exchange knowledge and experience in order to successfully complete the project.

Purchasing collaboration with other departments within the internal organisation

It can be stated that purchasing works as an intermediary between suppliers and the focal company and takes a role of a relationship manager. It should have the ability to communicate effectively including the potential contributions to design and technology experts internally. It is important to point out that the purchasing department does not have to coordinate all of the contacts with suppliers. Other important departments like Research and Development (R&D), Manufacturing or Sales may have the main and significant knowledge about a product and supplier market. In this context, a close collaboration between the departments is crucial.

The purchasing organization may not constantly play a major role but it should always be responsible for supplier selection, contracting and monitoring as well as maintaining right relationships. The following sections will describe the purchasing department's collaboration with other departments in the organisation. These departments are; R&D, manufacturing and logistics.

Purchasing R&D collaboration

Purchasing involvement in research and development activities has lately grown into a more strategic issue than ever before. Apart from the internal close collaboration between departments, firms look for supplier capabilities in engineering, design, testing, manufacturing, tooling, delivery and responsiveness. This new approach has been described by Narasimhan et al. (2001), which indicate that with the assurance of increased volume commitment and increased familiarity with a wider assortment of parts, suppliers can focus on design and process improvements.

Taking into account this reality, the role of purchasing involvement in product development has increased a lot. More than ever, the interdepartmental collaboration within research and innovation is essential for the company's long-term success and profitability. Leadership and joint problem solving implemented in purchasing organization are the tools to support developing critical products and process technologies.

Purchasing practices may involve extensive investments and development such as quality training for suppliers, organizational change towards integration, developing strong internal ties through membership in strategy development teaming, information sharing, and joint decision-making activities. The total costs tied up into these undertakings may be lowered by an efficient internal collaboration and planning. Further, these benefits can contribute to long-term profits and solid business establishment. For instance, the design for manufacturability can achieve lead-time reduction, better quality, less rework and cost reduction.

An effective collaboration between purchasing and product development can lead to better overall materials management in downstream processes inside the company. Bonaccorsi, et al. (1994) concluded in their field research that an early involvement of purchasing organization can enable efficient research within relevant suppliers and improve a company's performance in the future. However, it can only be achieved when the purchasing involvement and collaboration is managed carefully.

Most often the collaboration process with the R&D department involves contacting company's engineers regarding specific components, materials and technological solutions. Typically, growing degrees of project innovation and complexity are expected to lead to the increasing involvement of purchasers. The

level of purchasing contribution in product development can be diverse e.g. on part-time basis, fulltime basis and project coordination role.

According to the same author there must exist several factors that drive the need for purchasing collaboration:

- The presence of an internal organization that is able to support communication and coordination in product development

- The competences and sills of the purchasers in terms of personnel with the right education, skills and experience; understood as well-established purchasing organization

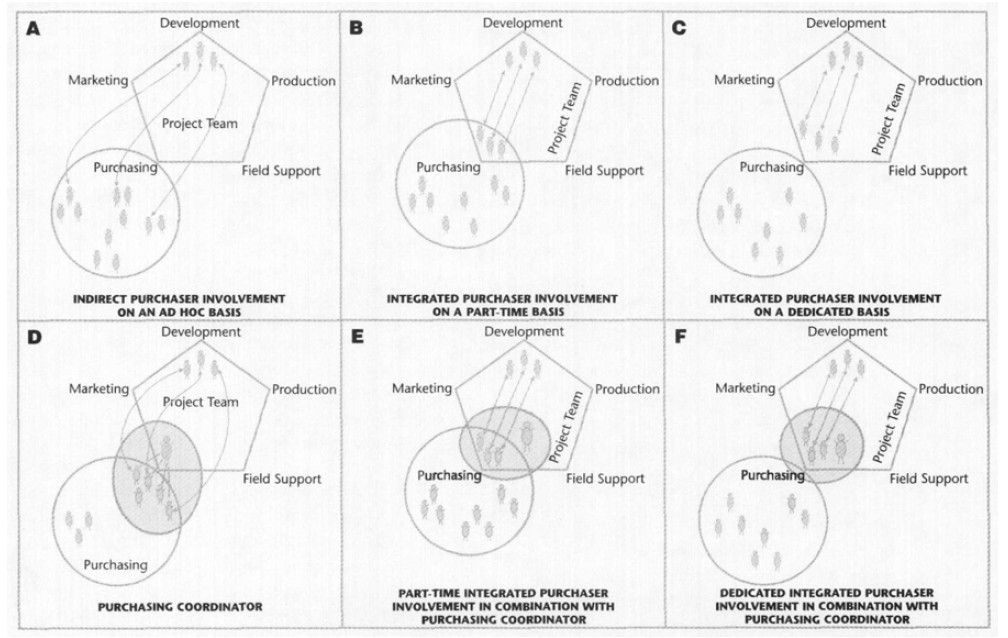

Figure 4 - Configurations of purchasing involvement in product development projects

Figure 4 presents different organizational mechanisms that have been suggested to coordinate functional interfaces between the departments of an organization. Purchasing can for instance become involved in a product development project based on direct collaboration between purchasers or developers and engineers. The purchasing is not really integrated in the project team but is involved occasionally when the support is needed. Generally speaking, the collaboration may have a dedicated basis (purchasers work full time in the development projects), a part-time basis (operational purchasing) or a coordination role where the project work is supported by the purchasing team from the department.

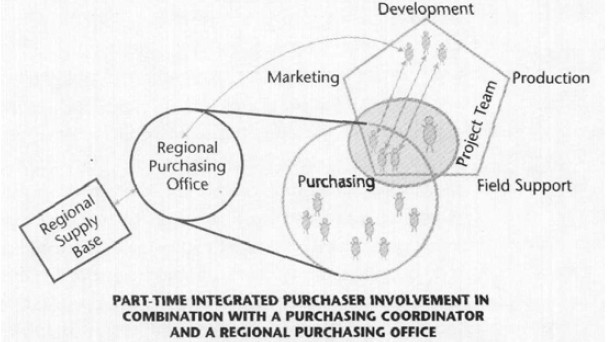

Figure 5 - The regional purchasing office for a regional supply base

Figure 5 presents another approach that is common for global companies. Increasing competition and market requirements put more conditions in many industries. Once, a Dutch manufacturer of copier and printing systems established a regional purchasing office in Asia, in order to reduce time-to-market of new products, decrease costs and intensify monitoring global development activities. Initially, the external supplier base was aimed at investigating the Asian supplier market. However, later it moved towards setting up a purchasing specialist role with the responsibilities of an account buyer and regional purchasing market researcher.

Purchasing and Manufacturing collaboration

There exists a strategic and meaningful relation between the activities performed by purchasing and manufacturing departments. Thoroughly selected suppliers and close relationship with them can support production efficiency and reliability. Watts, et al. (1992) emphasized the importance of achieving congruence between purchasing objectives, action plans, manufacturing and business goals.

To accomplish this, purchasing must be a full participant in business strategy formulation and implementation. Integration has become a new core competence for a lot of companies. In this part of the book, the central argument is that a well-aligned purchasing strategy has a crucial impact on the achievement of manufacturing and overall business goals.

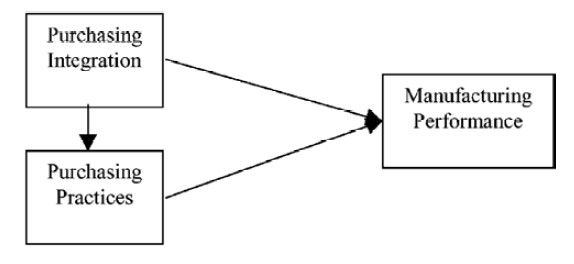

Figure 6 - Purchasing and manufacturing integration - Hypothesised model

The simple model presented on Figure 6 shows purchasing integration and purchasing practices as having a main influence on manufacturing performance. For instance, a positive connection between purchasing practices and manufacturing activities may be maintained by supplier integration and supply base management. Besides, purchasing integration can enhance the alignment between purchasing practices, and manufacturing and business priorities, making it easier for purchasing department to control management attention and secure organizational resources.

It is reasonable to argue that besides affecting manufacturing performance, purchasing integration can actually promote investments in purchasing practices that impact manufacturing performance (Narasimhan, et al., 2001). Efficient collaboration between these two departments with cooperation of R&D can positively affect cost-reduction and quality performance. Join decision-making processes enable building a value chain from introduction of new products to customization and reliable delivery.

It is important to understand that some of the purchasing strategic decisions i.e. supplier selection, contracting and supplier evaluation are not possible without close partnership of the manufacturing department. Very often it is the engineering knowledge that affects external collaboration with suppliers and enhances searching for new product possibilities.

In corporate reality, it is the production competences, capacities and efficiency that determine supplier selection and relationships. When it comes to manufacturing performance some of the new trends can be investigated. In the reality of the customer in focus and customization such strategies like engineer-to-order or build-to- order have been brought up. Companies tend to cut their overall supply chain costs as well as try to meet volatile customer expectations. Effective supplier relationship and performance support these strategies and enable high manufacturing efficiency. Besides, when introducing these new trends, close collaboration and information sharing is necessary i.e. supported by a system of order entry, customer monitoring, manufacturing, procurement and finance (Narasimhan, et al., 2001).

Nevertheless, surveys made in firms in production and service industries have shown a different perspective of purchasing integration. Accordingly, top management has low expectations of purchasing contribution into market planning, forecasting, innovation of products and strategy formulation. Most probably, it is because of lacking collaboration between departments, lack of commitment and a holistic view of the company. At the same time, large portion of the companies start to shift from the routine treatment of purchasing to proactive, cross-functional and more collaborative role (Petersen, et al., 2005).

Purchasing and Logistics collaboration

Maintaining efficient and on-time supply chain highly depends on the logistics performance. Supplier relationships and strategies determine logistical actions and put a challenge on the logistics department to perform cost-efficient and well-planned activities. In general logistics operations depend on geographical location of suppliers, type of goods, packaging and carriers as well as administrative issues. Demanding customers and cost-efficiency issues has lately put one more constraint on the logistics and transportation and it is Just-In-Time (JIT) approach (Christensen, 1996).

An enabler to fulfill all the requirements is the close collaboration between departments and mutual support. Purchasing organization should be aware of all the logistical issues when setting up new supplier strategies. Here the focus should be on scheduling, forecasting and positioning of inventories, capacity planning and transport distances.

The purchasing team should support the release of orders, quantity controls and scheduling. There are also a lot of visible benefits for buyers when they implement JIT purchasing. This includes reduction of the carrying costs for components, transport, rework, ease of expediting, fast detection of defects, fewer suppliers for contracting, less need for inspection, quick response to engineering changes. By cross-functional discussion the proper form, locations and shipment parameters must be discussed. Collaborate capacity planning must be done in order to maximize utilization of vehicles and decrease amount of waste e.g. waiting time, damages and shipment of wrong goods. Petersen, et al. (2005) emphasizes that collaborative actions require greater communication and information sharing between internal and external organizations. Also, he states that the collaborative planning can be expected to necessitate that the information shared is of high quality.

Well-organized and planned logistics actions very often have a high level of uncertainty. These, due to that many global businesses have faced the consequences of an increase in the distance between buyer and supplier and higher complexity of transport networks. The purchasing organization that works as an internal intermediary can support upstream and downstream activities in order to increase predictability and set accurate and realistic schedules.

Information sharing structures

Direct contact between employees from different departments can be enabled by creation of special collaboration role i.e. a person belonging to one of the involved departments with the responsibility for communicating and achieving coordination between the departments. A project manager is an example of a full-time integrator. Another possibility is creating a task force as a committee where certain issues are discussed by department representatives.

The most permanent option is crossfunctional teams often combined with project managers' actions. This will most probably fit into the product development activities that are very often carried out in teams (Lakemond, et al., 2001). Such activities address verbal and documented information exchanges between specific sides, including meetings, fax, teleconferencing, memoranda, conference calls and transmittal of standard documentation. By many practitioners interaction is considered as a tangible asset and can be easily monitored. (Kahn, et al., 1996)

Carter, et al. (2000) stated that:

“ Electronic commerce technology will support electronic efficiency efforts. Avery powerful communication integration is underway matching future improvements in the Web with the adoption of enterprise-based systems”.

The trend comes from an increasing need for efficient and integrated decision-making processes as well as service and product fulfilment to the customers. A lot of firms have decided to use the Internet, common databases and electronic access catalogues for fast and reliable information sharing as well as to support their business strategies e.g. Vendor Managed Inventory (VMI) or Pool-based systems. Such electronic solutions enable integration and collaboration between the departments inside the company. Internet, EDI (Electronic Data Interchange) messages and Enterprise Requirement Planning (ERP) systems are very often utilized in order tracking, financial transfers, production planning and scheduling, invoicing and other corporate activities. The use of EDI and Internet in purchasing will be further described in chapter.

When it comes to purchasing decisions supplier databases are created in order to keep track of supplier performance and enable future evaluation. Such information may be used by other departments like product development, production and logistics in order to support their planning and decision-making processes. The Internet era is now visible not only inside one company but also along supply chains in order to maintain global profitable strategies. Managers have realised that e- solutions can enhance SCM decision making by providing fast information and enabling external collaboration of trading partners (Gimenez, et al., 2008).

In one of his articles Carter, et al. (2000) has created a vision for future collaboration and importance of purchasing organization:

“ Strategic purchasing competency centres will be established at dominant companies with highly trained personnel who study their supply chains and search for opportunities to achieve competitive advantage through their choice of supply chain partners; determination of core competencies; and influence of design, manufacturing, operations and sourcing”

Conclusions

For many business representatives and supply chain practitioners purchasing is considered as a representation in top-level management, integrated with the support from cross-functional teams. In addition it is considered as having a meaningful contribution to competitive goals and overall corporate performance.

Another group of researchers has however discovered that the role of purchasers comes down only to tactical and supporting responsibilities. Both statements seem to be relevant, although it very often depends of the complexity of the corporation and type of business it performs. What we feel confident of is that purchasing organization is an important link inside the organization and internal collaboration. It plays a major role in materials management and information sharing and supports other departments, with the close cooperation with manufacturing and product development.

Whenever, internal collaboration issues are discussed, it is important to point out that a clear division of work and responsibilities must be done. All the departments should see it as sharing of risks but also mutual help and reward sharing, with the company's success in focus.

After reviewing many field studies and industry examples we strongly support the statement :

“ Purchasing plays a key role in supply chain management through its integration with production, scheduling, logistics, sales and accounting/finance. It has a proactive role to support the overall strategic plan and is regarded as an equal part of the corporate team”.