Supply Chain Management

- Details

- Category: Supply Chain Management

- Hits: 19,963

Supply Chain Management (SCM) is a crucial aspect of modern business operations, ensuring that products and services reach consumers efficiently and cost-effectively. It involves the coordination and integration of various activities, from raw material procurement to final delivery. In this blog, we will explore what supply chain management is, its key components, benefits, challenges, and emerging trends shaping the industry.

Understanding Supply Chain Management

At its core, Supply Chain Management is the management of the flow of goods, information, and finances as they move from supplier to manufacturer, wholesaler, retailer, and finally to the consumer. It integrates supply and demand management within and across companies, creating a seamless system that enhances efficiency and customer satisfaction.

SCM is not just about logistics; it encompasses procurement, production, inventory management, order fulfillment, and customer service. A well-structured supply chain can significantly impact an organization's bottom line by reducing costs, improving speed, and increasing flexibility.

Understanding Supply Chain Management

At its core, Supply Chain Management is the management of the flow of goods, information, and finances as they move from supplier to manufacturer, wholesaler, retailer, and finally to the consumer. It integrates supply and demand management within and across companies, creating a seamless system that enhances efficiency and customer satisfaction.

SCM is not just about logistics; it encompasses procurement, production, inventory management, order fulfillment, and customer service. A well-structured supply chain can significantly impact an organization's bottom line by reducing costs, improving speed, and increasing flexibility.

Supply Chain Management is essentially a network of independent organizations connected through products and services that they either separately or jointly add value to before delivering them to the final consumer. It is an extended concept of value addition, where businesses not only focus on their internal efficiencies but also on how they contribute to the larger supply chain ecosystem.

Evolution of Supply Chain Management

The need for supply chain management has become more apparent due to the changing business environment. Over the last few decades, business management has undergone significant transformations, with many traditional methods being replaced by new approaches such as business process re-engineering, strategic management, lean thinking, and agile manufacturing. Among these emerging disciplines, supply chain management has gained significant traction across industries worldwide.

The term "Supply Chain Management" first appeared in recognized literature in the early 1980s. In 1982, Oliver and Webber introduced the concept in a Financial Times article, where they described the range of activities involved in procurement and supply management. Initially, the focus of SCM was primarily on purchasing activities and cost reduction. However, in the 1990s, the concept evolved to include supply chain integration, supplier-buyer relationships, and overall coordination among different players in the supply chain.

Unlike traditional business concepts that have existed for centuries, SCM is a relatively new and evolving discipline. The growing adoption of supply chain management can be attributed to factors such as globalization, increasing competition, evolving customer expectations, technological advancements, and geopolitical influences.

Why Supply Chain Management Matters Today

The modern business landscape is more interconnected than ever before. Organizations no longer operate in isolation but as part of larger supply chains. This shift has led to a transformation in how competition is perceived. Instead of businesses competing individually, entire supply chains are now competing against each other.

The ability of a company to survive and thrive in today's market no longer depends solely on its internal efficiencies but on its capability to collaborate effectively within the supply chain. This interconnectedness means that businesses are highly interdependent; if one link in the chain fails, the entire chain can be affected. As the saying goes, "You either sink or swim with your supply chain."

Thus, businesses need to adopt a more strategic approach to managing their supply chains, focusing on collaboration, integration, and leadership. Relying solely on an internal, inward-looking management approach is no longer enough. Instead, organizations must align their strategic positioning, structural configuration, and operational efficiencies with their supply chain partners to gain a competitive edge.

The growing significance of SCM is not just a theoretical concept but is backed by real-world business performance improvements and market-driven results. Companies that have optimized their supply chains have reported increased efficiency, cost savings, and enhanced customer satisfaction.

The Ubiquity of Supply Chain Management

Supply Chain Management is pervasive across industries, influencing every aspect of business operations. It is difficult to find a business function that does not involve SCM in some capacity. For instance, consider quality management, a critical aspect of business success. Can an organization truly ensure high-quality standards for its products or services without managing its suppliers and buyers within the supply chain? The answer is no.

Business value creation is a collective effort that involves the entire supply chain. From procurement to customer service, each segment plays a role in delivering value to the end consumer. This holistic approach to management underscores why SCM has become an indispensable element of modern business strategy.

Key Components of Supply Chain Management

To better understand SCM, let’s break it down into its essential components:

1. Planning

SCM begins with planning, which involves forecasting demand, managing inventory levels, and designing a supply chain strategy. Effective planning ensures that supply meets demand, minimizing shortages or excess inventory.

2. Sourcing

Sourcing involves selecting suppliers that provide raw materials or components needed for production. Companies must evaluate factors such as cost, quality, reliability, and supplier relationships to ensure a steady supply of materials.

3. Manufacturing

This stage includes the production or assembly of goods. It involves quality control, labor management, and efficiency optimization to ensure products meet standards and are produced cost-effectively.

4. Inventory Management

Proper inventory management prevents overstocking or stockouts, reducing storage costs and ensuring a steady flow of goods. Techniques like Just-In-Time (JIT) inventory management help companies maintain optimal inventory levels.

5. Logistics and Transportation

Logistics involves moving goods from suppliers to manufacturers, warehouses, and finally to customers. Choosing the right transportation mode (air, sea, rail, or road) and optimizing routes are crucial to reducing costs and delivery times.

6. Order Fulfillment

This component involves processing customer orders, packaging, and shipping products. Efficient order fulfillment ensures timely delivery and enhances customer satisfaction.

7. Returns Management (Reverse Logistics)

Handling product returns, repairs, and recycling is also part of SCM. A well-managed reverse logistics process helps recover value from returned goods and minimizes waste.

Benefits of Supply Chain Management

Effective SCM offers numerous benefits to businesses and consumers alike:

1. Cost Reduction

By optimizing processes, companies can reduce waste, lower transportation costs, and improve efficiency, leading to significant cost savings.

2. Improved Customer Satisfaction

A well-managed supply chain ensures timely deliveries, quality products, and better service, enhancing customer experience.

3. Greater Efficiency

Integrated supply chain processes improve coordination, reduce bottlenecks, and increase productivity.

4. Risk Mitigation

SCM helps identify potential risks, such as supply disruptions or demand fluctuations, allowing companies to develop contingency plans.

5. Competitive Advantage

Companies with efficient supply chains can respond quickly to market changes, giving them a competitive edge over rivals.

Challenges in Supply Chain Management

Despite its benefits, SCM also presents challenges that businesses must navigate:

1. Supply Chain Disruptions

Natural disasters, geopolitical tensions, or pandemics can disrupt supply chains, leading to delays and increased costs.

2. Demand Fluctuations

Unexpected changes in customer demand can lead to stockouts or excess inventory, affecting profitability.

3. Globalization Complexities

Operating in multiple countries introduces complexities such as compliance with different regulations, currency fluctuations, and cultural differences.

4. Sustainability Concerns

Companies are increasingly pressured to adopt sustainable practices, reducing carbon footprints and minimizing waste.

5. Technological Integration

Adopting new technologies such as AI, blockchain, and IoT requires significant investment and skilled personnel.

Emerging Trends in Supply Chain Management

To stay competitive, businesses are adopting new trends in SCM:

1. Digital Transformation

Companies are leveraging AI, big data, and cloud computing to enhance visibility, automate processes, and improve decision-making.

2. Blockchain for Transparency

Blockchain technology enhances transparency by providing a tamper-proof record of transactions, improving trust among stakeholders.

3. Artificial Intelligence and Machine Learning

AI-driven analytics help predict demand, optimize routes, and improve inventory management.

4. Sustainability Initiatives

Businesses are focusing on eco-friendly packaging, renewable energy, and ethical sourcing to meet consumer and regulatory expectations.

5. E-commerce and Omnichannel Strategies

With the rise of e-commerce, companies are implementing omnichannel strategies to provide seamless shopping experiences across multiple platforms.

Defining supply chains

Plowing through the plethora of literature, one will come to realize that there are as many different definitions who explain what is supply chain management as many of those who cared to write about it. However, a broad conceptual consensus on the notion of Supply Chain (SC) and Supply Chain Management (SCM) is beyond anybody’s reasonable doubt. Based on that, the author would like to offer his definition of SC here and SCM in the next section.

In this definition, there are a number of key characteristics that have been used to portrait a supply chain. First, a supply chain is formed and can only be formed if there are more than one participating companies. Second, the participating companies within a supply chain normally do not belong to the same business ownership, and hence there is a legal independence in between. Third, those companies are inter-connected on the common commitment to add value to the steam of material flow that run through the supply chain. This material flow, to each company, comes in as the transformed inputs and goes out as the value added outputs.

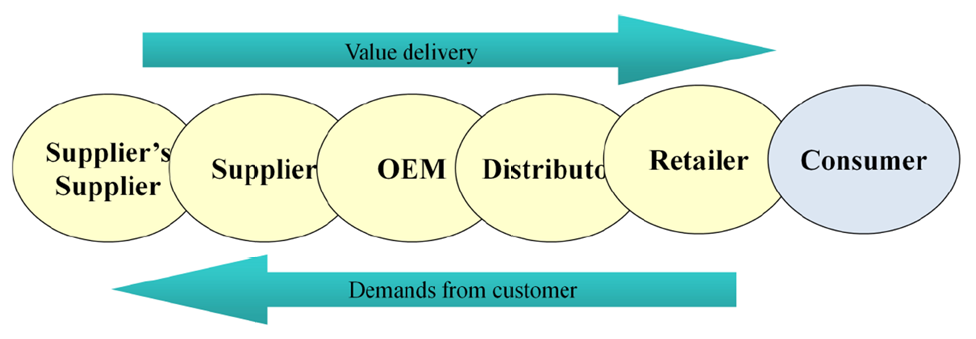

Intuitively, one can imagine a supply chain as something resembles a “chain”, in which the “links” are the participating companies that are inter-connected in the value adding process (see figure 1). The link on the upstream side of the material flow is the supplier’s supplier; and on the downstream side of the material flow is the customer. There is usually an OEM – Original Equipment Manufacturer in between. The OBM sometimes is represented by OBM – Original Brand Manufacturer, or sometimes simply the “focal company.”

Figure 1. The basic Supply Chain model

At the end of a supply chain is the product and/or service that are created by the supply chain for the end consumer. Thus, the fundamental reason of a supply chain’s existence is hinged on to serving the end-consumer in the market place. Thedegree of how well a supply chain can serve their consumer ultimately defines its competitive edge in the market place.

It is understandable that in real-world a supply chain is much more complex than the one depicted in Figure1. It is not really a “chain”, rather it is more like a “network”, when you consider that there are usually multiple suppliers and multiple customers for each participating companies in the chain. There are also possible nested chains within the chains. For example an engine manufacturing supply chain is a nested supply chain within the connected automobile supply chain.

Depend on how would like to see the supply chain, there are similar but different names you may like to call the supply chain. If you view a supply chain as basically a chain of value adding activities, you may like to call it “Value Chain”; if you perceive a supply chain as continuous demands originated from the consumer and stretched to upstream suppliers, you may like to call the supply chain the “Demand Chain”.

Since the business connections between organisations are pervasive, how could one draw a boundary of a supply chain?

In order to answer this question, one needs to understand the four intrinsic flows of a supply chain.

Material Flow

All manufacturing supply chains have material flows from the raw materials at the beginning of the supply chain to the finished products at the end of the supply chain. A furniture-making supply chain will have the wood cut down from forest at the beginning of its supply chain and home furniture at the end of supply chain.

The continuous flow of wood been transformed through the chain and end up to furniture ties the whole supply chain together and defines its clear boundary. A furniture supply chain can never be confused with a chocolate manufacturing supply chain because the material flows in between are clearly different and never will they cross with each other.

Information Flow

All supply chain s have and make use of information flows. Throughout a supply chain there are multitude of information flows such as demand information flow, forecasting information flow, production and scheduling information flows, and design and NPI information flows. Unlike the material flow the information can run both directions, towards upstream and downstream alike. Interestingly most of them are unique to the specific supply chain.

The information of woman’s fashion clothing has no value to a motorbike supply chain. Any supply chain will have its own set of information flows that are vital to its existence which are often jealously protected against those of other supply chains.

Finance Flow

All supply chain have finance flow. It is basically the money flow or the bloodstream of a supply chain. Without it, a supply chain will surely demise. However, for any supply chain, there is only one single source of such finance flow – the en-consumer.

This understanding of single source of finance has led to a concept of “single entity” perspective of a supply chain, which is a very useful foundation for supply chain integration and collaboration. The distribution and sharing of this single financial resource fairly across a supply chain will allow for the better alignment between the contribution and reward for the participating companies.

Commercial flow

All supply chain represents a transactional commercial flow. This means that the material flow that run through the supply chain changes its ownership from one company to another, from supplier to buyer. The transactional process of buying and selling shifts the material flow’s ownership from the supplier to the buyer repeatedly until the end of the supply chain – the end-consumer.

This transactional commercial flow will only take place in a supply chain where there are more than one companies. On the other hand, if it is with an organisation there will be material flow, but no ownership change, and hence no commercial flow.

The four flows described above not only better explain the function of the supply chain, but also define it more rigorously. They represent four major areas of concerns and research activities in the supply chain management, which covers most of the known issues in the published literatures.

Customer Orientation

Having understood the supply chain model, one may ask “Is the end-consumer a part of the supply chain?” Most people will say “Yes”, because consumer give the demand information; consumer provide the financial reward and so on. But the author will argue that strictly speaking the end-consumer is NOT part of the supply chain; the supply chain only extend from the very raw material suppliers to the retailer (if that’s the last link in the supply chain before the end-consumer).

There are number of fundamental reasons to support this argument.

- First, all supply chain supplies, and every member of the supply chain supplies; but the consumer DON’T, it demands instead of supply. The fundamental function of a supply chain is to supply; and the consumer is the recipient of the supply, but not a part of the supply. Supply chain’s existence is based on the existence of the demand from the consumer. Supply chain treats consumer as the object which it serves. If a supply chain contains the consumer within itself, then it will have no object to serve and no recipient to take the supply; and it will lose its purpose of existence.

- Second, a supply chain adds value to the product (or transformed inputs), but the consumer DON’T. Consumer consumes the product and depletes its market value. Used goods are always cheaper than the new ones. A supply chain and every member in it have the irrefutable duty to add values to the material flow, and they must learn how to improve the business and its management; but consumers will never need to do that. Their job is to use the money to vote which supply chain best satisfy their demand.

- Third, a supply chain is always specialised and a consumer is always general. A computer manufacturing supply chain only produces computers, whilst a consumer will have to buy food, clothing, and automobile as well as computers. Due to the extremely divers nature of consumer’s purchasing, to put the consumer as part of a supply chain will not be helpful in understanding the nature of a supply chain and may cause considerable confusion theoretically and logically.

Based on these three fundamental differences between the nature of supply chain and that of the consumer, it is more appropriate and less confusion if we separate the consumer away from the concept of the supply chain. This definition of supply chain without consumer will not deprive the immense benefits that consumer may contribute to the supply chain. How the end-consumer plays this pivotal role in the existence and the management of supply chain is the core notion of supply chain management.

The end-consumer to a supply chain is perhaps the most important factor of all as far as its management is concerned. Everything a supply chain does is driven by the needs and wants of the end-consumer.

The contents of SCM are populated with the approaches, activities as well as the strategies that are aiming at delivering the products and services to satisfy the end-consumer. Therefore, it is safe to say that the SCM should be and has always been a customer centred management. This reflects the typical characteristic of supply chain’s customer orientation.

Not only the end-consumer serves as the ultimate objective, it also provides vital information and practical assistance to the decision making in the process of supply chain management. The end-consumers needs and wants, where they are, how many they are and how much they can afford and etc. give the supply chain manager some very precise guidance as how to achieve market responsiveness.

It is therefore beyond the shadow of doubt that supply chain and its management have always been, still are, and will certainly continue to be customer oriented. This customer orientation gives the fundamental reason and purpose of its existence. It also ensures that supply chain management has to be a system perspective based management approach that engages every participating member of the supply chain to align to the customer orientation.

Defining Supply Chain Management

Defining the supply chain management can be both dead easy and extremely difficult. It is dead easy because it is so widely known and widely practiced in almost all businesses. There is hardly a need to teach the “A, B, C” again. It is also extremely difficult because the definition must capture all what is supply chain management in practice has reached far and wide. As an attempt, the author proffers the following definition:

This definition squared out the nagging confusion between organisational business management and supply chain management. Rarely any aspect of organisational business management is not related to or influenced by the external firms in the supply chain. Thus the best way to manage the business is to take into consideration and engage with the external organisations in the decision making in order to achieve the ultimate business objectives – that means supply chain management.

In other words, trying to identify a set of supply chain management activities that is not or nothing to do with any known business management activities would futile. The inception of the supply chain management concept did not create a new set of functional activities that has never been carried out before. What it created is a new way of understanding on how the business activities might be better carried out.

The supply chain management defined as such has already elevated the modern business management concept from the organisational focused domain to the supply chain focused system giving rise to more effectiveness in achieving the strategic objectives. Today’s competition is no longer seen as the company against the company but the supply chain against the supply chain. Supply chain management is therefore a new perspective towards the old activities.

This definition effectively explains why supply chain management can be done in such vastly diverse ways; why apparently completely different management activities can often be called supply chain management; why the same traditional management function is now been entitled as supply chain management; and so on. The answer is simply that because we start view the management issues and taking actions from the supply chain perspective.

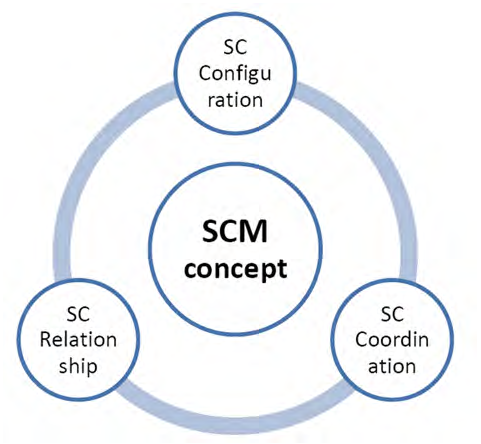

This definition certainly gives the supply chain management concept a ubiquitous and pervasive nature. But, that does not mean that there is nothing uniquely identifiable on its own. One can still identify some practically very useful conceptual components of the supply chain management. Any supply chain management practice and activities is captured by the three conceptual components: Supply Chain Configuration; Supply Chain Relationship; and Supply Chain Coordination.

Figure 2. Supply Chain Management conceptual model

- Supply Chain Configuration is about how a supply chain is constructed from all its participating firms. This includes how big is the supply base for OEM (original equipment manufacturer); how wide or narrow is the extent of vertical integration (which is the single ownership of consecutive activities along the supply chain); how much of the OEM’s operations are outsourced; how the downstream distribution channel is designed; and so on. It is also known as supply chain architecture. The decision on supply chain configuration is strategic and at a higher level.

- Supply Chain Relationship is about inter-firm relationships across the supply chain albeit the key focus of relationship is often around the OEM and its first tier suppliers and first tier customers and the relationship in between. The type and level of the relationship is determined by the contents of inter-organisational exchanges. The relationship is likely to be “arm’s length” if they only exchanged the volume and price of the transaction; on the other hand, the relationship would be regarded as close partnership if the parties exchanged their vision, investment planning, NPI process and detailed financial information. The decision on supply chain relationship is both strategic and operational.

- Supply Chain Coordination refers mainly to the inter-firm operational coordination within a supply chain. It involves the coordination of continuous material flows from the suppliers to the buyers and through to the end-consumer in a preferably JIM manner. Inventory management throughout the supply chain could be a key focal point for the coordination. Production capacity, forecasting, manufacturing scheduling, even customer services will all constitute the main contents of the coordination activities in the supply chain. Thedecision on the supply chain coordination tends to be operational.

There is, however, one thing in common amongst the three key supply chain management focuses. That is they all deal with the external organisation in the same supply chain, which makes the concept more supply chain rather than organisationally internal.

These concepts also tell us that supply chain management involves managerial decision making across strategic, tactic and operational levels – the pervasiveness. One may notice that all the major Operations Management text books will include a chapter or two on supply chain management, but that does not necessarily make the subject purely operational.

Development Trends

Another difficulty in understanding and defining supply chain and supply chain management is that it is never stand still and the subject has been continuously evolving since its inception in the early 1980s. The continuous development is partly propelled by the changes of overall business environment and heightened competitions in the global market place. But partly it is influenced by the new understanding of the supply chain that they participate. There are number of early development trends that can be observed evidently.

From functional to process perspective

Business management used to see and take action on the functional silos in the business. It was understandable that naturally the function is what seen to be the delivery part of the business. But, today with supply chain management concept managers can see their problems more from the process perspective, understanding that functions can only make sense if it is perceived from a supply chain process perspective.

From operational to strategic viewpoint

At early years of applying supply chain management concept,managers tends to see it as another operational tactics that will help to reduce operational cost, such as purchasing function improvement and optimising the logistics operations. But, gradually more and more managers realised that the effective changes can only be achieved if the operational issues are addressed from the supply chain wide strategic viewpoint. Operational excellence can only be manifested through its strategic fit.

From single enterprise to extended enterprise

Enterprise management is now arguably displaced by the supply chain management, where the supply chain is by definition the extended enterprise. The long established enterprise centred management thinking was based on that the competition was raged between the organisations, thus it becomes obsolete as the competitions are now predominantly between the supply chains. Management thinking over the extended enterprise produces a great deal ideas that single enterprise alone cannot.

From transactional to relationship based engagement

Business engagement between firms in the past was predominantly transaction based and cost driven. The merit of any purchasing and procurement of externally sourced materials and services was judged by the transactional measures such as price, volume and delivery terms. But what’s now more of the practices in working with external organisations within the supply chain is so called relationship based engagement.

This relationship approach does not abandon the transactional activities but put its decision baking on much wider consideration of knowledge exchange, long-term commitment, incentives and reward.

From local to regional, and from regional to global

Connections of supply network have over the last two decades grown from local to regional and to global. Hardly any major enterprise and supply chains is not connected to some part of the world. You need to get out before you can get up. This trend is spurred by the lower cost of labour and materials in many parts of the world, as well as first mover advantages in setting up global market presence.

The trends of supply chain development are not always positive and encouraging. There is now enough evidence to support that supply chain risks are now continuously growing to the level that is higher than ever before; and supply chain integration still remains as the major management shortfall across all industrial sectors (PRTM Global supply chain trends report 2010-12).

The task of managing and improving supply chain performances across all industrial sectors is only becoming tougher, not easier. This calls for deeper and more thorough understanding of the challenges supply chains are facing.

Supply Chain Management is the backbone of modern business, ensuring that goods and services reach consumers efficiently. By understanding its components, benefits, challenges, and emerging trends, businesses can optimize their supply chains to stay competitive in a dynamic global market. As technology continues to evolve, companies that embrace innovation and sustainability will lead the future of supply chain management.

FAQ about Supply Chain Management

1. What is supply chain management in simple terms?

Supply chain management (SCM) is the coordination of all processes involved in producing and delivering goods—from raw materials to final customer delivery—ensuring efficiency, cost-effectiveness, and customer satisfaction.

2. Why is supply chain management important for businesses?

SCM is crucial for minimizing costs, improving delivery times, enhancing customer satisfaction, and gaining a competitive edge in a global market. It ensures that the entire product journey is optimized.

3. What are the main components of supply chain management?

The key components of supply chain management include planning, sourcing, manufacturing, inventory management, logistics, order fulfillment, and returns management—each playing a vital role in operational efficiency.

4. What are the biggest challenges in supply chain management?

Common SCM challenges include supply disruptions, demand fluctuations, globalization complexities, sustainability pressures, and the need for technological integration like AI and blockchain.

5. What are the emerging trends in supply chain management?

Emerging trends include digital transformation, AI-powered logistics, blockchain for transparency, sustainability initiatives, and omnichannel fulfillment driven by the rise of e-commerce.